In the past two years, solar module technology has changed, and various companies have competed in an "arms race" in photovoltaic modules technology. From size changes to solar cell technology iterations, everyone has shown their own housekeeping skills.

In terms of the recent N-type solar module technology route dispute, JinkoSolar has set a new world record for the conversion efficiency of large-area N-TOPCon cells, with a conversion efficiency of 25.4%. At the same time, LONGi has once again made a major breakthrough in the M6 size heterojunction cell (HJT), with a conversion efficiency as high as 26.30%. Judging from the current industry situation, N-TOPCon is more favored by mass production manufacturers. What is it that supports this technology?

1. The past and present of TOPCon solar panel technology

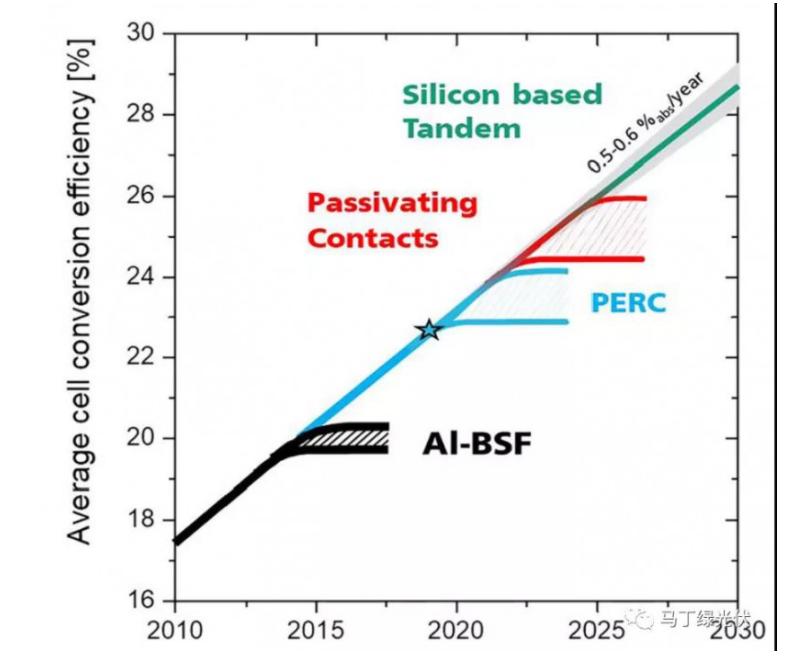

The core of Topcon technology lies in passivating contact. The second half of Topcon is the abbreviation of Passivating Contact. One of the core points to improve solar cell efficiency is to continuously reduce the recombination of electron and hole pairs, from polycrystalline to single crystal, from all-aluminum backfield to PREC, step by step, and continuously reduce internal consumption, gradually by 0.5% The efficiency improvement rate of -0.6%/year is undergoing iteration.

M. Hermle, et al., Appl. Phys. Rev. 7, 021305 (2020).

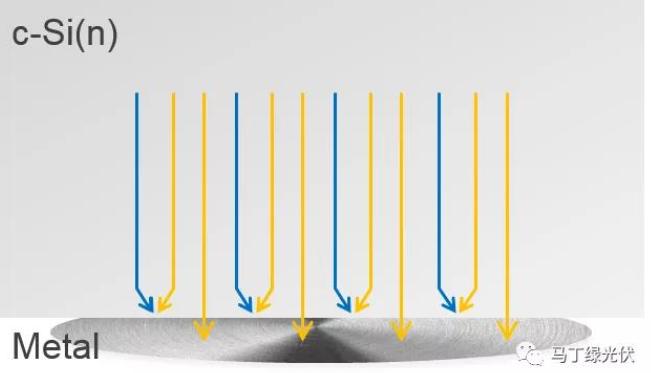

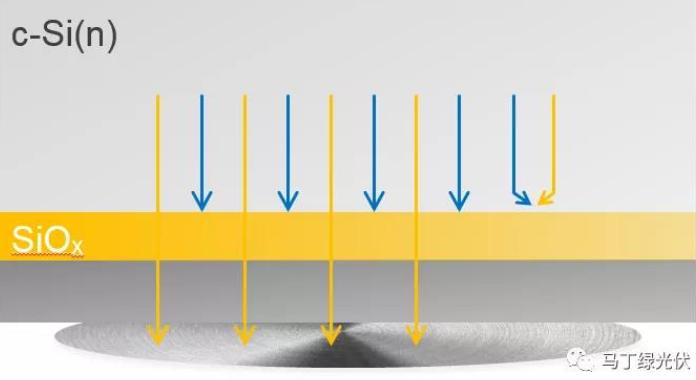

The passivation contact of PERC can be regarded as an incomplete body of TOPCon. Compared with the previous all-aluminum back-field solar cell (the back of the solar panel cell is all aluminum except for the silver electrode), the back of the PERC solar module cell reduces the proportion of aluminum, and uses a passivation layer such as SiNx to passivate where there is no aluminum. The back surface reduces the recombination of the metal-semiconductor interface, increases the voltage, and increases the conversion efficiency. However, the metal electrode structure of PERC solar cell still retains a small amount of metal-semiconductor contact area. Don't underestimate the contact area at this point. It is one of the dominant factors of recombination and an important factor limiting the breakthrough of PERC cell efficiency.

TOPCon's solar panels cell design further reduces the metal-semiconductor contact area, and goes further and further on the road of reducing recombination, constantly moving closer to the ideal solar cell, and constantly breaking through the efficiency barrier. As shown in the figure below, the contact between the metal and the semiconductor is eliminated, and the tunneling effect is used for conduction.

P.P. Altermatt, Nature Energy 3, 718 (2018)