With the continuous progress of photovoltaic technology R&D and industrialization, the conversion efficiency of crystalline silicon solar cells has gradually entered the ranks of ≥26%. Martin Green’s solar cell efficiency table (version 58) released by Progress in Photovoltaics shows that the conversion efficiency is ≥ The 25.5% efficiency crystalline silicon solar cell adopts the passivation contact structure. As early as 2019, the company used passivating contact structure technology in mass production cells, using a tunnel oxide passivating contact (Tunnel Oxide Passivating Contact) solar cell technology based on the selective carrier principle, referred to as TOPCon technology can effectively reduce surface recombination and metal contact recombination, providing more room for the conversion efficiency of N-type solar panel cells.

TOPCon solar module cell technology advantages

Passivation advantage

Surface passivation performance mainly depends on chemical passivation and field passivation. Thermally grown SiO2 has excellent chemical passivation ability. Heavy doping in polysilicon can induce bending of the energy band of silicon, resulting in the accumulation of majority carriers and the depletion of minority carriers at the interface, reducing recombination, and playing the role of field passivation. To

Metal contact compound advantage

Metal contact recombination has become a bottleneck that limits the efficiency of conventional solar cells. In industrialization, the metallization method is usually high-temperature sintering after screen printing. During the high-temperature sintering process, the metal paste will "etch" poly-Si to form "Spiking", destroying the passivation contact structure and leading to the metal contact area. The J0c is higher than the passivation area. But the metal contact recombination of p+ poly and n+ poly can make the metal recombination far lower than the conventional emitter/back field even if the "piercing" will destroy the passivation contact structure.

Metal contact resistivity advantage

In addition to metal contact recombination, metal-semiconductor contact resistivity (ρc) is also very important to the device performance of crystalline silicon solar cells. The formation of good ohmic contacts between metal-semiconductors can help reduce resistance loss and increase fill factor.

It is reported in the literature that the ρc of p+ poly can achieve 4.0~10.0 mΩ•cm2, which is slightly higher than that of the p-type doped layer formed by screen printing silver paste, and the ρc of n+ poly can achieve 0.5~2.0 mΩ•cm2, which is slightly lower. In the n-type doped layer, ρc is formed by screen printing silver paste.

Therefore, the advantages of low interfacial recombination, low metal contact recombination and low metal contact resistivity of the polysilicon passivation contact structure have promoted the conversion efficiency of solar cells to a new level, making TOPCon cells a recognized successor to p-PERC in the industry. One of the mainstream solar cell structures afterwards.

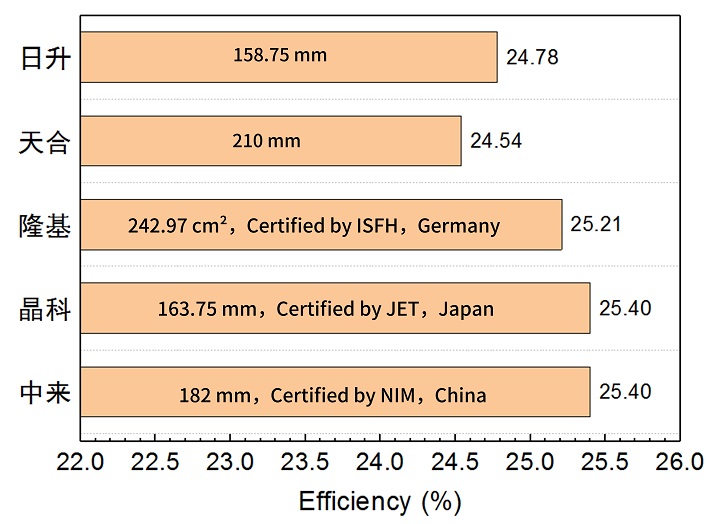

TOPCon solar cell industrialization progress

In view of the advantages of N-type TOPCon solar cell's high conversion efficiency, high reliability and low temperature coefficient, many leading domestic solar cell manufacturers have invested heavily in the research and development and industrialization of TOPCon solar cell technology, as the first batch of leaders to enter the TOPCon field Enterprises, the company has used years of hard work to explore the way for the photovoltaic industry.